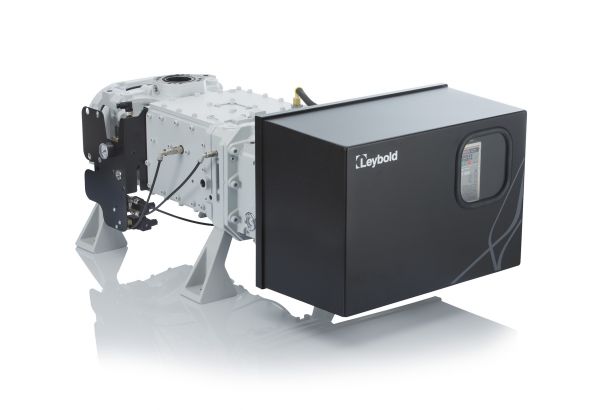

DRYVAC DV 200

| Porta di collegamento : | DN 63 ISO-K |

| Pressione finale: | 5 x 10-2 mbar |

| Velocità di pompaggio: | 210 m3/h |

DRYVAC DV 200

Dry compressing screw vacuum pump

Smart engineering for today and tomorrow: our network-capable DRYVAC series delivers cutting-edge performance and efficiency, even when the going gets tough.

This series of dry compressing screw-type vacuum pumps is engineered for the connected age. Packed with intelligent features and functions, all DRYVAC models offer seamless connectivity, networked control and superior efficiency.

DRYVAC pumps boost your productivity, minimize your carbon footprint, and lower your costs. Plus, thanks to an integrated smart service concept, they virtually look after themselves.

Connected, efficient, reliable – smarter with Leybold.

Built-in intelligence for industrial applications

Seamless connectivity & networking

Seamless connectivity & networking

Fieldbus and PLC compatibility allow for connectivity to other devices in a network for real-time communications and control. Direct control is also possible via a computer or handheld device. Support for various fieldbus protocols ensures maximal flexibility. Protocol support for Profibus, Ethernet/IP, ProfiNet and EtherCAT as option.

Intelligent energy consumption

Intelligent energy consumption

The low constant power consumption delivers siginificant energy efficiency. The advanced self-regulating feature, only consumes the power the pump actually needs, saving costs and reducing your carbon footprint. DRYVAC pumps are more cost-efficient and greener than similar models operating in the low-pressure range (<10 mbar).

Smart service concept

Smart service concept

Continuous performance monitoring made possible via an integrated frequency converter and three independent sensors. Should abnormal conditions such as overheating be detected, DRYVAC pumps can communicate them quickly and efficiently via fieldbus. Preset parameters enable plug-and-play operation, without additional installation.

DRYVAC pumps also feature minimal maintenance and easy cleaning of water cooling channels thanks to a non-jacketed design.

Characteristics

-

Hermetically sealed screw vacuum pump with integrated frequency converter

-

Simple mechanical and electrical integration

-

Integrated protection functions of temperature, exhaust pressure and power consumption monitoring

-

Small footprint due to compact design

-

Low energy consumption achieved through optimized rotor geometry and innovative motor design with efficiency class IE3

-

Tolerant to dust ingress

-

Excellent condensable gas (water vapor) performance

-

High pumping speed also at high intake pressures

Technical data

| Max. pumping speed | 210 m3/h 124 cfm |

| Ultimate pressure (w/o gas ballast) | < 0.05 mbar < 0.04 Torr |

| Permissible ambient temperature | 5 to 50 °C |

| Noise level with silencer at ultimate pressure | 65 dB(A) |

| Relative ambient atmospheric humidity | 90%, non-condensing |

| Max. installation height | Up to 2000 m above sea level |

| Cooling | Water |

| Cooling water temperature range | 5 to 35 °C |

| Cooling water nominal flow | 8 l/min |

| Mains voltage 50/60 Hz | 200-240 V ±10% or 380-460 V ±10% |

| Rated power 50/60 Hz | 7.5 kW |

| Power consumption at ultimate pressure | 4.1 kW |

| Bearing lubricant | LVO 210 synthetic oil |

| Protection class | IP54 |

| Intake connection | DN 63 ISO-K |

| Discharge flange | DN 40 ISO-KF |

| Weight, approx. | 370 kg |

| Dimensions (W x H x D) | 1110 mm x 613 mm x 478 mm |

Monitoring

-

Pressure switch on exhaust side (1.2 bar abs.)

-

Temperature pump housing

-

Temperature motor

-

Current limits through frequency converter

Equipment

-

Integrated frequency converter

-

Electro pneumatic gas ballast valve 24 VDC

-

Purge gas valve 24 VDC

- Product brochure (967.39 Kb)

- Product Overview (11.65 Mb)

- Product Overview (9.83 Mb)

- Declaration of contamination (HS1) (531.93 Kb)

- Declaration of contamination (HS2) (602.15 Kb)

- Dichiarazione di contaminazione (HS1) (497.16 Kb)

- Dichiarazione di contaminazione (HS2) (613.18 Kb)

- Product catalogue (4.88 Mb)

- Service catalogue (1.71 Mb)